Demand Peripherals

Robotics and Automation Made Easy

Demand Peripherals

Robotics and Automation Made Easy

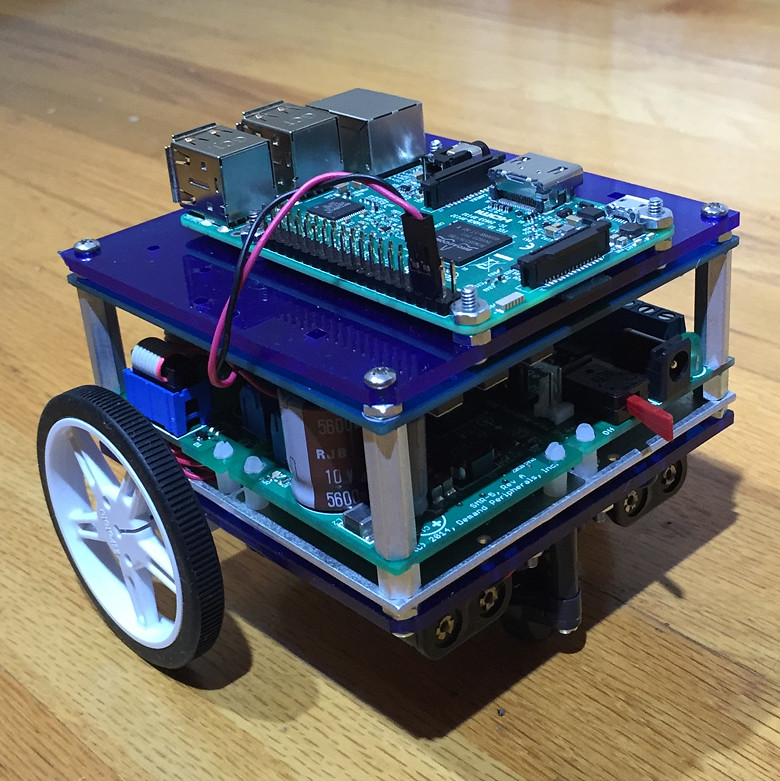

The Peripheral Control project from Demand Peripherals makes it

easy to build a Linux based robot or other automation. Our

key differences are a Linux API and the 100 percent code reuse

that seems inherent with FPGA based peripherals. No more

having to write all of the software layers from the hardware

up to your application.

The Peripheral Control project from Demand Peripherals makes it

easy to build a Linux based robot or other automation. Our

key differences are a Linux API and the 100 percent code reuse

that seems inherent with FPGA based peripherals. No more

having to write all of the software layers from the hardware

up to your application.

The API is ASCII commands over a TCP connection. This means

you can write your Linux application in almost any programming

language: C, C++, Java, Perl, PHP, or Python. We even have

BASH wrappers around the commands so you can program or test

your automation from the command line!

The video to the right is a nice introduction to FPGA-based

controllers and to the simple API we offer. After watching

the video you will have a full understanding of what it does,

how it works, and how to use it in your application.

Changing peripherals is easy. Just go to the support page Build Your FPGA Image, select your new peripheral set, tell us where to email the FPGA image and press Submit. The email address associated with your purchase of the FPGA card gives you access to the backend service that builds FPGA images. There is no limit on how many FPGA images you can request.

Demand Peripherals can dramatically improve your time-to-market

for new robots or other automation since there is no MCU

code to write and interface card schematics are open-source.

The design cycle for building a microcontroller based robot

is eight to twelve months just to get to the point that you

can start writing the high-level Linux application. The

problem is that you usually have to start from scratch for

the circuit design and all of the MCU code.

A typical workflow when using Peripheral Control is to build

a prototype using off-the-shelf cards. This prototype

will be API complete and ready for use by the high level

application programmers. Once the application is underway

on the prototype hardware you can have your electrical engineers

collect the schematics and arrange them on one board

and start the board layout and fabrication. The advantage

in this approach is there is no MCU firmware to write

and you can have an API complete prototype in a week.

The Peripheral Control FPGA code is free for non-commercial use.

The daemon is released under the GPLv3 and the schematics are

released under a Creative Commons license. To use the system

commercially requires a purchased license. the license costs

seventy-five

hundred dollars and includes the following:

- Ability to distribute the FPGA image

- Non Creative Commons use of the schematics

- Non GPL use of the pcdaemon source code

- License for the patented circuit of the ESPI

- Five hours of telephone support

Need help with the schematic capture and board layout? Let us know. Demand Peripherals can help build your prototypes.

A detailed description of the system operation and architecture can be found here.

A list of the peripherals and their descriptions can be found here.

A list of interface cards can be found here.

A complete description of the API can be found here.

You can specify and build a custom FPGA image with your selection of peripherals here.